Core Processes and Applications

• Process Overview: First, a physical object is scanned using a 3D scanner to obtain a massive amount of surface data points, forming a point cloud.

This data is then processed using reverse engineering software to construct a precise 3D model (i.e., reverse modeling).

Finally, this digital model can be used for 3D printing to create a new physical object.

• Cultural Relic Restoration and Reproduction: Damaged cultural relics are scanned and virtually restored and fully modeled on a computer.

3D printing technology is then used to create replicas, preserving the originals while making them accessible to a wider audience.

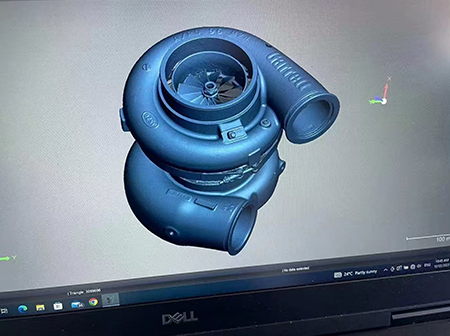

• Industrial Part Reproduction and Improvement: For old parts without original drawings, scanning and reverse engineering can be used to recreate their 3D models for replica production or optimized design.

• Personalization: Scanning a specific body part, such as a foot, hand, or head, provides accurate data for customized footwear, prosthetics, glasses, helmets, and more.

• Film, TV, and game props: Scan actors' faces to create high-precision masks or digital doubles;

Scan real-world scenes for game modeling, greatly enhancing realism.

High-precision 3D Scanning Reverse Modeling: Specifications, Maintenance, and Performance

High-precision 3D scanning reverse modeling is a transformative technology widely adopted across industries such as aerospace, automotive, healthcare, and manufacturing. This advanced technique allows for the creation of highly accurate digital models from physical objects using 3D scanning technology. By capturing detailed geometries and converting them into CAD models, it offers significant advantages for reverse engineering, prototyping, and product optimization.

This article provides an in-depth look at the packaging specifications, maintenance requirements, technical indicators, and product performance of high-precision 3D scanning reverse modeling solutions. It is tailored for professionals and organizations looking to understand the full scope of benefits and requirements of using this technology in modern product development.

High-precision 3D scanning reverse modeling involves the use of 3D scanning technology to capture physical objects' geometries and convert them into precise digital models. These digital models are often in the form of 3D CAD files, making them suitable for use in manufacturing, design, and analysis. The process typically involves several steps, including:

Scanning: Using a laser scanner or structured light scanner to capture the detailed shape of an object, creating a point cloud of data.

Data Processing: Cleaning, aligning, and converting the point cloud data into a polygon mesh that accurately represents the object’s geometry.

Modeling: Converting the mesh into a fully editable CAD model that can be used for design or reverse engineering.

Analysis and Modifications: Engineers or designers can now analyze the model, make design changes, and prepare it for prototyping or manufacturing.

This method is ideal for reverse engineering, where original design files may be missing, or for product optimization, where a physical object needs to be modified or improved.

High-precision 3D scanning reverse modeling systems require specialized packaging to ensure the safe transport and storage of the equipment. Proper packaging is essential for protecting sensitive scanning hardware and software components.

| Component | Specification |

|---|---|

| Scanner | Shock-resistant foam casing, moisture-proof packaging. |

| Cables and Accessories | Organized in protective pouches to prevent tangling or damage. |

| Software | Delivered in secure, sealed packaging, with license codes and installation instructions. |

| Manuals and Documentation | Printed and digital copies in a protective folder. |

| Transport Container | Sturdy, hard-shell case with reinforced corners to prevent external pressure damage. |

Temperature: Store in a dry, climate-controlled environment with temperatures between 15°C to 25°C (59°F to 77°F).

Humidity: Maintain humidity levels between 30% and 50% to prevent corrosion of sensitive components.

Handling: Always lift the equipment with care, using appropriate support structures to avoid damage during transportation.

By following these packaging specifications, manufacturers can ensure that their high-precision 3D scanning systems are protected during transit, reducing the risk of damage and maintaining system performance upon arrival.

Maintaining a 3D scanning reverse modeling system is essential for ensuring long-term functionality and performance. Regular maintenance minimizes downtime, ensures high-quality scans, and extends the lifespan of the equipment.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Calibration | Every 3-6 months | Recalibrate the scanning system to ensure precise data capture. |

| Cleaning Scanning Lenses | Weekly | Use a soft microfiber cloth to clean lenses and sensors. |

| Software Updates | As needed | Regularly check for and install software updates to enhance performance. |

| System Performance Check | Monthly | Run diagnostic tests to ensure optimal functionality. |

| Hardware Inspection | Quarterly | Inspect cables, mounts, and sensors for wear and tear. |

Calibrate regularly: Calibration ensures that the scanning system provides accurate and repeatable results.

Update software: Ensure that the scanning and modeling software is up-to-date to benefit from new features, improved accuracy, and bug fixes.

Use proper cleaning techniques: Dust or debris on lenses or sensors can degrade scan quality. Use a compressed air blower or microfiber cloth to gently clean the equipment.

Regular diagnostics: Periodically run diagnostic tools to identify potential issues before they impact system performance.

Maintaining your 3D scanning reverse modeling system according to these guidelines will help to ensure reliable, high-quality data capture and processing over time.

Understanding the technical capabilities of a high-precision 3D scanning system is essential for determining its suitability for specific applications. The following indicators are key to evaluating system performance:

| Technical Indicator | Description |

|---|---|

| Resolution | The minimum detectable feature size of the scanner, typically measured in microns. A higher resolution allows for capturing finer details. |

| Accuracy | The degree to which the scanned data matches the actual dimensions of the object. High accuracy is crucial for reverse engineering applications. |

| Scan Speed | The rate at which the scanner can capture data. Faster scan speeds improve efficiency, especially for large objects. |

| Measurement Range | The maximum size of the object that can be scanned accurately. This varies depending on the type of scanner and the application. |

| Data Density | Refers to the number of points captured per unit area. Higher data density results in finer and more detailed models. |

| Compatibility | The ability of the system to work with various CAD software and file formats such as STL, OBJ, or STEP. |

Resolution: 0.1mm or better for high-precision applications.

Accuracy: ±0.02mm for reverse engineering and part replication.

Scan Speed: 0.5m²/min or higher for faster processing.

Measurement Range: 1m to 5m, depending on the scanner type.

Data Density: 1,000,000 points per scan or higher for complex geometries.

These technical indicators help users assess the suitability of a 3D scanning system for specific tasks, ensuring that the system meets the required standards for precision and performance.

The performance of high-precision 3D scanning reverse modeling systems is critical for achieving accurate results in reverse engineering, product optimization, and prototyping. The following aspects of performance should be considered when selecting or evaluating a system:

Faster Data Capture: Modern 3D scanners are capable of capturing large datasets in a short amount of time, improving productivity and enabling quick iterations during product development.

Data Processing Time: After scanning, data processing can take varying amounts of time depending on the complexity of the object. Efficient software solutions can significantly reduce post-processing times.

High Accuracy: The accuracy of the 3D scanning system is one of the most critical factors for reverse engineering applications. High-precision systems provide sub-millimeter accuracy, ensuring that every detail of the physical object is captured.

Detail Preservation: High-quality scans preserve fine details, which is especially important for applications like aerospace, where intricate features must be replicated with no deviation from the original design.

User Interface: Intuitive software and an easy-to-navigate user interface improve workflow and minimize the learning curve for new users.

Customization: Many systems offer customizable settings for resolution, scan speed, and accuracy, allowing users to adapt the system to their specific needs.

High-precision 3D scanning reverse modeling is a powerful technology that enhances the accuracy and efficiency of reverse engineering, product design, and prototyping. By understanding the packaging specifications, maintenance requirements, technical indicators, and product performance, users can maximize the value of their 3D scanning systems.

Whether you are in the aerospace, automotive, or medical device industry, adopting high-precision 3D scanning technology will provide you with faster prototyping, improved accuracy, and better product development capabilities. Regular maintenance and understanding the technical capabilities of your system will ensure it continues to deliver high-quality results over time, optimizing both performance and cost-effectiveness.

Investing in a high-quality 3D scanning reverse modeling system is essential for businesses looking to stay ahead in competitive markets where precision and innovation are key.

This website uses cookies to ensure you get the best experience on our website.