Core Processes and Applications

• Process Overview: First, a physical object is scanned using a 3D scanner to obtain a massive amount of surface data points, forming a point cloud.

This data is then processed using reverse engineering software to construct a precise 3D model (i.e., reverse modeling).

Finally, this digital model can be used for 3D printing to create a new physical object.

• Cultural Relic Restoration and Reproduction: Damaged cultural relics are scanned and virtually restored and fully modeled on a computer.

3D printing technology is then used to create replicas, preserving the originals while making them accessible to a wider audience.

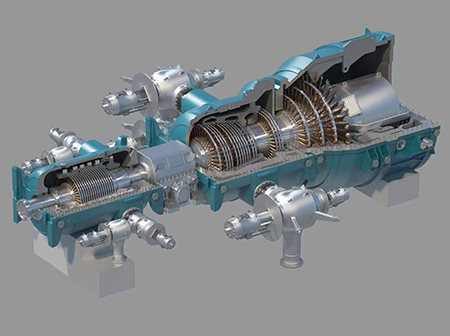

• Industrial Part Reproduction and Improvement: For old parts without original drawings, scanning and reverse engineering can be used to recreate their 3D models for replica production or optimized design.

• Personalization: Scanning a specific body part, such as a foot, hand, or head, provides accurate data for customized footwear, prosthetics, glasses, helmets, and more.

• Film, TV, and game props: Scan actors' faces to create high-precision masks or digital doubles;

Scan real-world scenes for game modeling, greatly enhancing realism.

3D Scanning Reverse Data Optimization Processing: Maintenance, Tips, Product Overview, and Safety Guidelines

3D scanning reverse data optimization processing is a transformative technique that allows industries to create precise and optimized digital representations of physical objects. By employing 3D scanning technology, businesses can capture complex geometries of real-world objects, which are then processed and optimized for reverse engineering, prototyping, and design optimization. This technology has wide-ranging applications across industries like automotive, aerospace, medical, and manufacturing, where precision is crucial.

In this article, we will cover the key aspects of 3D scanning reverse data optimization processing, including its maintenance frequency, operation tips, product introduction, and safety instructions. By the end, you will have a comprehensive understanding of how to use, maintain, and safely operate 3D scanning systems to achieve optimal results in your production processes.

3D scanning reverse data optimization processing is the process of converting real-world physical objects into highly detailed and editable digital models. The process involves using 3D scanners to capture the physical object’s geometry, creating point cloud data. This data is then processed, cleaned, and optimized to produce CAD models that are ready for reverse engineering, manufacturing, or prototyping. The optimization part focuses on improving the quality and usability of the scanned data, ensuring that the final model is efficient for production.

High Precision: The technology allows for highly accurate scans that capture minute details of complex shapes.

Time Efficiency: It significantly reduces the time required to replicate or reverse-engineer a part, speeding up product development.

Cost Savings: With optimized scanning and processing, businesses can save costs on physical prototyping and error correction.

Improved Design: It enables easy modifications to existing designs, optimizing for performance, durability, or manufacturability.

Versatility: Applicable across multiple industries including automotive, aerospace, healthcare, and more.

3D scanning reverse data optimization systems are designed to meet the needs of industries that require high-quality, precise, and optimized digital models. The system typically consists of the following components:

3D Scanner: A high-precision device that captures the geometry of an object by measuring its surface using laser scanners, structured light scanning, or contact-based methods.

Data Processing Software: Software that transforms the raw data from the scanner (often in the form of point clouds) into a cleaned-up and optimized CAD model.

Post-Processing Tools: These tools further refine the 3D model by smoothing surfaces, filling holes, and correcting minor errors to make the model suitable for reverse engineering or manufacturing.

Export Functionality: The final optimized models are usually exported in various file formats (e.g., STL, STEP, OBJ) for use in 3D printing, CNC machining, or CAD software.

Reverse Engineering: Creating digital replicas of parts for analysis or replication.

Prototyping: Quickly creating prototypes based on digital models for testing and validation.

Quality Control: Comparing physical parts with digital models to ensure they meet design specifications.

Customization: Creating custom parts based on customer needs or specific requirements.

Regular maintenance of 3D scanning and reverse data optimization systems is essential to ensure that they operate efficiently and provide accurate results. Below is a guideline on how frequently maintenance should be performed and the key steps for proper upkeep.

| Component | Maintenance Frequency | Maintenance Action |

|---|---|---|

| 3D Scanner Calibration | Every 3-6 months | Regularly calibrate the scanner to ensure accuracy. |

| Software Updates | As available | Install software patches and updates to improve functionality and performance. |

| Lens and Sensor Cleaning | Weekly or after heavy use | Clean the scanning lenses and sensors to avoid dust buildup, which can affect scan quality. |

| Data Storage and Backup | Monthly | Back up scanned data and CAD models to ensure data integrity and prevent loss. |

| Hardware Checkups | Quarterly | Inspect the physical condition of the scanner and accessories, checking for wear and tear. |

Keep the scanner in a clean, dry environment to prevent dust and moisture damage.

Protect the scanner from physical shocks that may misalign internal components.

Check cables, connectors, and accessories regularly for wear and damage, as these are critical for data transfer and power supply.

Store the scanner in a protective case or on a dedicated shelf when not in use to avoid accidental damage.

Proper operation is key to achieving the best results with your 3D scanning and reverse data optimization system. Below are essential tips for getting the most out of your equipment.

Lighting: Ensure that the object being scanned is well-lit but not exposed to harsh direct lighting that could cause reflections.

Object Stability: The object should be firmly secured during scanning to avoid movement, which can lead to inaccurate data.

Background Noise: Avoid cluttered or reflective backgrounds that could interfere with the scanning process.

Multiple Scans: Capture the object from different angles to ensure that all surfaces are covered. Overlapping areas help improve the accuracy of the model.

Resolution Settings: Adjust the resolution settings depending on the level of detail needed. Higher resolution scans may take longer to process but provide greater accuracy.

After scanning, use data processing software to remove noise and correct any inaccuracies. This step ensures that the data is clean and usable for reverse engineering or prototyping.

Optimize Mesh Quality: If your model has a high polygon count, consider simplifying it for faster processing and smoother export.

Integrate scanned models with CAD software to compare and further modify the design. Ensure that the exported model is compatible with your design software for seamless integration.

Although 3D scanning systems are generally safe to use, following safety guidelines is essential to avoid accidents and ensure long-term system health.

Electrical Safety:

Ensure that the scanner and associated devices are plugged into grounded power sources.

Avoid overloading power circuits when using additional equipment like computers or external monitors.

Laser Safety (for laser-based scanners):

Avoid direct eye exposure to the laser beam, as it can cause serious damage to the retina.

Use the scanner only in environments where the laser beam is controlled and not aimed at bystanders.

Physical Safety:

Handle equipment with care to prevent physical damage, especially to lenses and sensors.

Ensure that all components, such as cables, are securely connected before powering up the system to prevent short circuits.

Environmental Safety:

Avoid using the scanning equipment in extreme temperatures or humid environments.

Store the system in a dust-free area to prevent contamination of sensitive equipment.

3D scanning reverse data optimization processing is a powerful tool that enables businesses to create precise digital models for reverse engineering, prototyping, and design optimization. By maintaining regular maintenance schedules, following proper operation practices, and adhering to safety guidelines, companies can ensure the longevity and performance of their scanning systems.

With the right equipment and techniques, 3D scanning systems can significantly improve production efficiency, reduce errors, and enhance the quality of both prototypes and finished products. By understanding and implementing these best practices, businesses can maximize the return on investment in their 3D scanning technology and achieve higher-quality results in their product development processes.

This website uses cookies to ensure you get the best experience on our website.